Home » Product Detail

Products

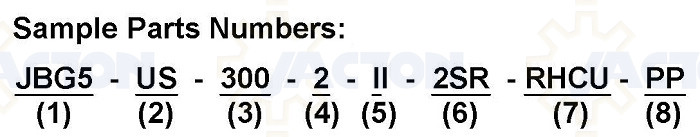

Sample Part Number of Super High Speed Screw Jacks

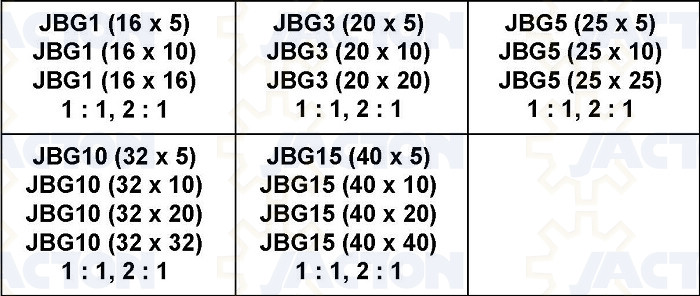

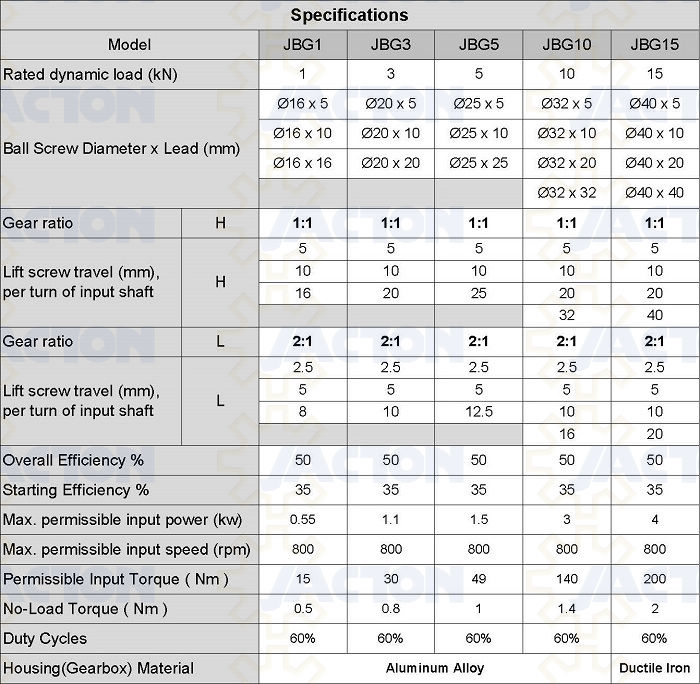

Model: 1000N to 15000N

Brand Name: Jacton

Order Quantity: MOQ 1pc Acceptable

Product Origin: Guangdong, China

Assembly Drawing: 3D (stp, step, model, igs), 2D (dwg, dxf), PDF

Delivery Time: 10-15 Working Days After Payment

Payment Methods: T/T, PayPal, Western Union, MoneyGram

Transportation Modes: Air Freight, Sea Freight

Shipment Port: Shenzhen, Guangzhou, Hongkong

Packages: Strongest Exporting Plywood Cases

Description:

Sample Part Number of Super High Speed Screw Jacks

Note: For multiple high speed quick lifting screw jacks lifting systems, some bevel gear jacks require left-handed ball screw. However, there are not high(large) leads sizes for left-handed ball screws. Please pay more attention when selection.

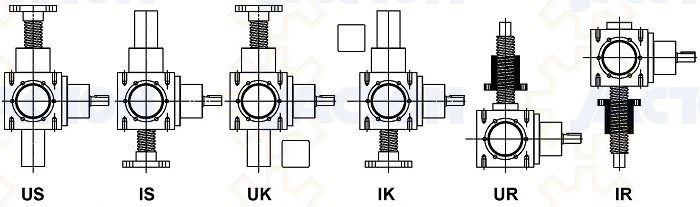

(2) Configurations and Designs

* US: Upright mount, Translating Screw.

* IS: Inverted mount, Translating Screw.

* UR: Upright mount, Rotating Screw with lifting nut.

* IR: Inverted mount, Rotating Screw with lifting nut.

* UK: Upright mount, Anti-rotation Screw (Square tube).

* IK: Inverted mount, Anti-rotation Screw (Square tube).

* Important Note: The lifting ball screw of a translating screw jack must be attached to the guided load which prevents the lifting ball screw from rotating. To add the linear guides, rails or rolls are recommended.

* Important Note: If your application involves a load which is unattached, unguided or the load is free to rotate and not translate, then an anti-rotation screw jack(square tube and nut) are required to prevent lifting ball screw rotation (not recommended).

* Important Note: Without self-locking, may lower under load. Brake motors or external locking devices are recommended.

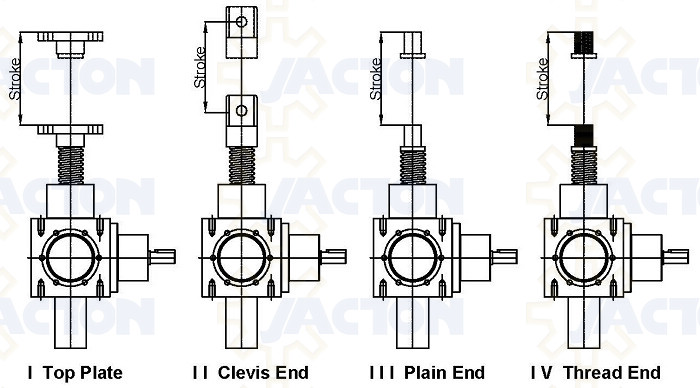

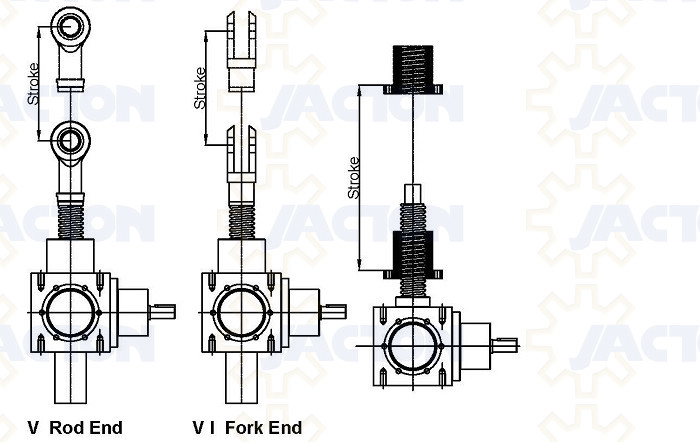

(3) Stroke and (5) Screw End Fittings

* Stroke is travel expressed in millimeter(mm) or inches and not the actual screw length.

* Standard Screw End Fittings: top plate(load pad), clevis end(male clevis), plain end, threaded end. Also rod end, and fork head(female clevis) are available. Custom screw ends are acceptable.

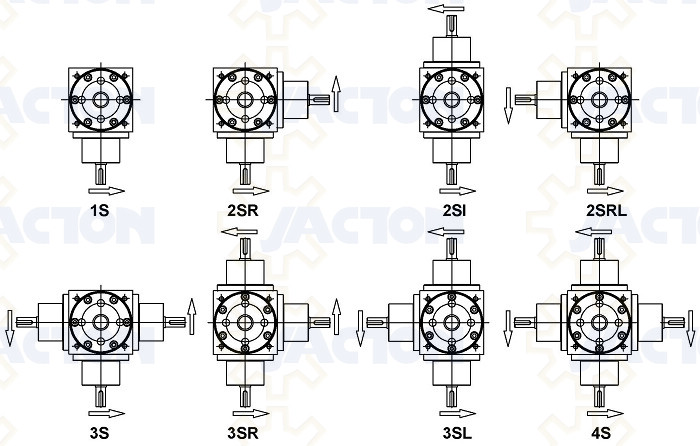

(6) Input Shaft Codes

Note: The gearbox space is limit, except 1S and 2SI type, other types are not suitable for 1:1 ratio, but 2:1 ratio is available for all types.

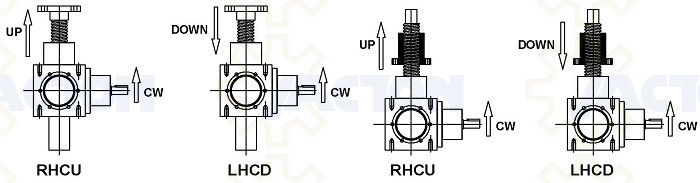

(7) Ball Screw or Ball Nut Direction of Movement

* RHCU: Right-handed Screw. When the input shaft rotates clockwise, the ball screw or ball nut moves up.

* LHCD: Left-handed Screw. When the input shaft rotates clockwise, the ball screw or ball nut moves down.

Note: When the input shaft rotate counterclockwise, the direction of movement is the opposite.

(8) Additional Accessories

* Motorized driven (AC or DC) by asynchronous motors (normal, YEJ brake, YVP variable frequency, B explosion proof, D multi-speed), stepper motors, servo motors with encoders and controllers. IEC motor flange or NEMA C-Face motor adapter for connect with motors. Frequency inverters.

* Manually operation by Aluminum handwheels, or Cast iron handwheels.

* Connection Devices: Couplings. Universal joints. Telescopic universal joints. Connecting shafts.

* Screw Protective Devices: Bellows boot. Telescopic spring covers. Rigid Protective tubes.

* Safety Devices: Limit switches. Proximity switches. Safety nuts. Anti-backlash nut. Overload safety couplings. Stop nuts. Position Encoders. Overload clutch. Brake motor. Linear braking elements. Wear detection/monitors. Linear guides and rails. Potentiometer. Pressure sensor.

* Others Accessories: Travel nuts. Position indicators. Trunnion adapter plates. Trunnion mounting brackets. Pillow blocks. Flange blocks. Rod end bearings.

Previous Product:15KN bevel gear jack with ball spindle, miter bevel gear jack

Next Product:none

Products List

Contact Us

JACTON INDUSTRY CO.,LTD.

Building 2, No. 1,

Dongcheng Road, Chang An,

Dongguan, Guangdong, China.

Post Code: 523880

Tel: +86 769 8158 5810

Fax: +86 769 8158 5852

Email: sales@jactonindustry.com

Email: jactonjack@gmail.com

Whatsapp: +86 13532830851

Wechat: +86 13532830851

Skype: jactonjack

TradeManager: jactonjack

Online QQ: 2512868631

Website: www.jactonindustry.com

Building 2, No. 1,

Dongcheng Road, Chang An,

Dongguan, Guangdong, China.

Post Code: 523880

Tel: +86 769 8158 5810

Fax: +86 769 8158 5852

Email: sales@jactonindustry.com

Email: jactonjack@gmail.com

Whatsapp: +86 13532830851

Wechat: +86 13532830851

Skype: jactonjack

TradeManager: jactonjack

Online QQ: 2512868631

Website: www.jactonindustry.com

Products

- Screw Jack with Handwheel

- Screw Jack with Motor

- Cubic Machine Screw Jacks

- Cubic Ball Screw Jacks

- Single Face Machine Screw Jacks

- Single Face Ball Screw Jacks

- Single Face Stainless Steel Screw Jack

- Bevel Gear Machine Screw Jacks

- Bevel Gear Ball Screw Jacks

- Super High Speed Screw Jacks

- Electric Cylinder Actuators

- Parallel Electric Linear Actuators

- Inline Electric Linear Actuators

- Electro-Mechanical Linear Actuators

- Compact Cubic Bevel Gearboxes

- Bevel-T Right Angle Gearboxes

- Aluminum Housing Gearboxes

- Servo Spiral Bevel Gearboxes

- Multiple Screw Jack Lifting Systems

Supports

JACTON INDUSTRY CO.,LTD.

Building 2, No. 1,

Dongcheng Road,

Dongguan, Guangdong, China

Post Code: 523880

Phone:+86 769 8158 5810

Email:sales@jactonindustry.com

Building 2, No. 1,

Dongcheng Road,

Dongguan, Guangdong, China

Post Code: 523880

Phone:+86 769 8158 5810

Email:sales@jactonindustry.com

English Site |

Chinese Site |

|

|

JACTON INDUSTRY CO.,LTD | VAT No. 9144190007026567X3 | Website Legal Notice | Privacy Policy | Terms and Conditions

Copyright © 2018 JACTON INDUSTRY CO.,LTD All Rights Reserved | Design By:Jacton | Youtube | Facebook | LinkedIn | Twitter | Pinterest | Google+ | Sitemap