Home » Product Detail

Products

20 kN Capacity Higher Duty Cycles Ball Screw Jacks

Model: JTD25-20 kN-32x5-Travel 10-2000MM

Brand Name: Jacton

Order Quantity: MOQ 1pc Acceptable

Product Origin: Guangdong, China

Assembly Drawing: 3D (stp, step, model, igs), 2D (dwg, dxf), PDF

Delivery Time: 10-15 Working Days After Payment

Payment Methods: T/T, PayPal, Western Union, MoneyGram

Transportation Modes: Air Freight, Sea Freight

Shipment Port: Shenzhen, Guangzhou, Hongkong

Packages: Strongest Exporting Plywood Cases

Description:

Jacton 20 kN capacity higher duty cycles ball screw jacks have the greater efficiency and rolling action, the ball screw can operate at higher speeds or increased duty cycle when compared with the machine screw jack. The addition of a high efficiency ball screw and nut reduces the required input torque. The ball screw sizes 32x5, worm gear ratios 6:1 and 24:1.

Features of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

1. Upright or inverted units with maximum static load capacity 20 kN in tension or compression.

2. Required input torque to approximately one-third the torque required for the machine screw jack. They also require a brake motor or external locking device to hold position.

3. Ball screw sizes 32mm diameter, lead 5mm (single start ball nuts and ball screws).

4. Worm gear set gear ratios 6:1 and 24:1 ratios.

5. There are no standard travel lengths and each ball screw jack is built to specification.

6. Standard configurations: upright or inverted translating ball screw jacks, upright or inverted translating with anti-rotation ball screw jacks, and upright or inverted rotating ball screw jacks.

7. They can be driven by different motors: electric motors, dc motors, gear motors, as well as hydraulic or pneumatic motors. Also they can be driven by hand wheels or cranks or with any other kinds of transmission.

8. Can be applied singularly or in groups as a synchronous lifting system which properly connected with drive shafts, universal joints, and bevel gearboxes.

Structures of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

1. Ball screw and nut made from hardened alloy steel with hardened bearing balls carrying the load between nut and screw.

2. Worm input shaft in case-hardened steel C45.

3. High strength aluminum bronze worm gears (drive sleeve).

4. Housing of nodular cast iron.

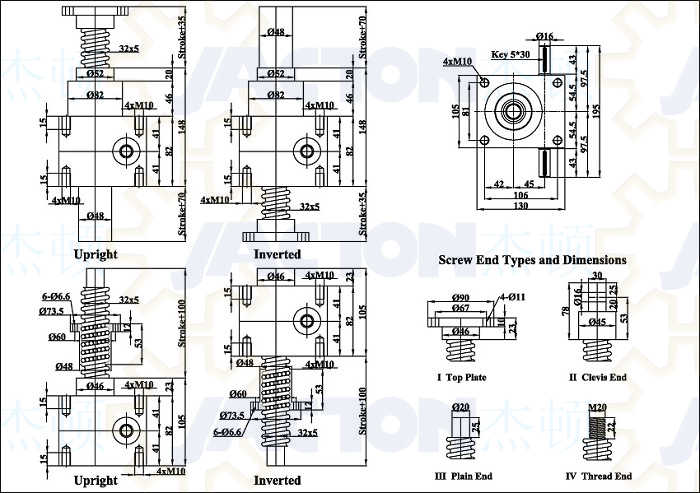

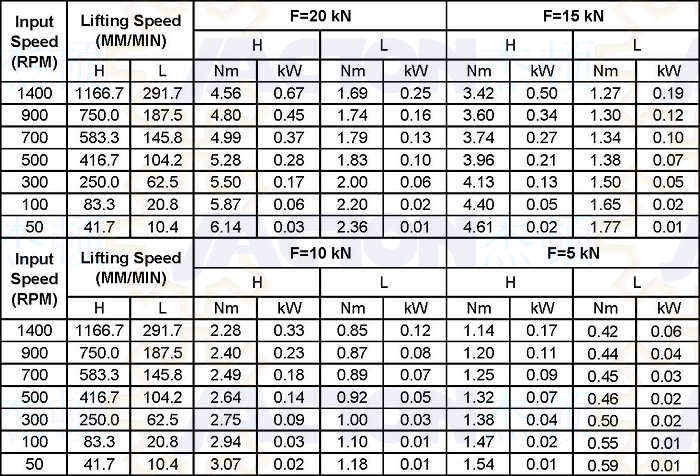

Specifications of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

The specifications of 20 kN capacity higher duty cycles ball screw jacks include maximum load capacity, worm screw diameter and pitch, worm gear ratio, allowable maximum input power, torque and speed and overall efficiency etc.

1. Conditions: within 20% running time/60 minutes or within 30% running time/10 minutes, 20 ��C ambient temperature. Maximum allowable input power (high ratio) 1.14kw, maximum allowable input power (slow ratio) 0.55kw.

2. Note: When your selection is exceed the maximum input power, the operational restrictions due to thermal limits. you will need to choose the bigger size screw jacks in order to allow effective heat dissipation.

3. H=high ratio 6:1 (0.83mm stroke for one input turn), L=slow ratio 24:1 (0.21mm stroke for one input turn).

4. Nm=input torque required, kW=input power required.

5. Selection of screw jacks using above figures should only be carried out in consultation with Jacton engineers.

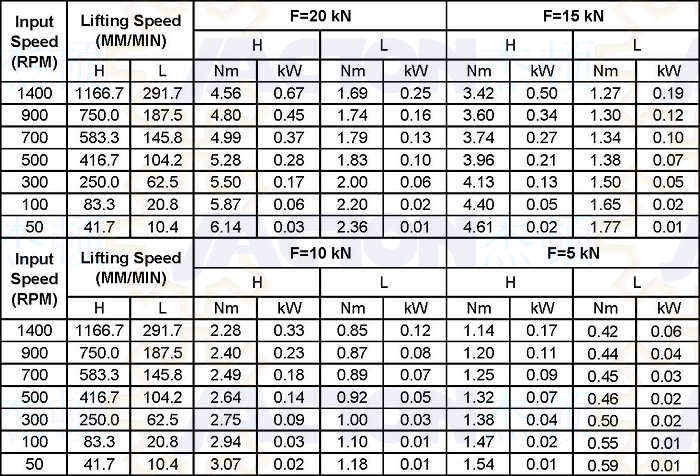

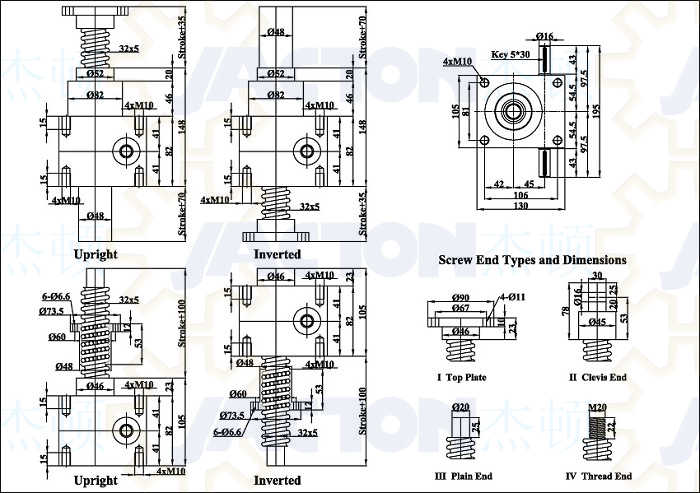

Assembly Drawings of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

Find out 20 kN capacity higher duty cycles ball screw jacks front view, side view and top view assembly drawings. About 2D Autocad dwg, dxf assembly drawings, and 3D stp, step, model, igs, prt or catpart assembly drawings, please contact us directly.

Features of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

1. Upright or inverted units with maximum static load capacity 20 kN in tension or compression.

2. Required input torque to approximately one-third the torque required for the machine screw jack. They also require a brake motor or external locking device to hold position.

3. Ball screw sizes 32mm diameter, lead 5mm (single start ball nuts and ball screws).

4. Worm gear set gear ratios 6:1 and 24:1 ratios.

5. There are no standard travel lengths and each ball screw jack is built to specification.

6. Standard configurations: upright or inverted translating ball screw jacks, upright or inverted translating with anti-rotation ball screw jacks, and upright or inverted rotating ball screw jacks.

7. They can be driven by different motors: electric motors, dc motors, gear motors, as well as hydraulic or pneumatic motors. Also they can be driven by hand wheels or cranks or with any other kinds of transmission.

8. Can be applied singularly or in groups as a synchronous lifting system which properly connected with drive shafts, universal joints, and bevel gearboxes.

Structures of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

1. Ball screw and nut made from hardened alloy steel with hardened bearing balls carrying the load between nut and screw.

2. Worm input shaft in case-hardened steel C45.

3. High strength aluminum bronze worm gears (drive sleeve).

4. Housing of nodular cast iron.

Specifications of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

The specifications of 20 kN capacity higher duty cycles ball screw jacks include maximum load capacity, worm screw diameter and pitch, worm gear ratio, allowable maximum input power, torque and speed and overall efficiency etc.

1. Conditions: within 20% running time/60 minutes or within 30% running time/10 minutes, 20 ��C ambient temperature. Maximum allowable input power (high ratio) 1.14kw, maximum allowable input power (slow ratio) 0.55kw.

2. Note: When your selection is exceed the maximum input power, the operational restrictions due to thermal limits. you will need to choose the bigger size screw jacks in order to allow effective heat dissipation.

3. H=high ratio 6:1 (0.83mm stroke for one input turn), L=slow ratio 24:1 (0.21mm stroke for one input turn).

4. Nm=input torque required, kW=input power required.

5. Selection of screw jacks using above figures should only be carried out in consultation with Jacton engineers.

Assembly Drawings of 20 kN Capacity Higher Duty Cycles Ball Screw Jacks

Find out 20 kN capacity higher duty cycles ball screw jacks front view, side view and top view assembly drawings. About 2D Autocad dwg, dxf assembly drawings, and 3D stp, step, model, igs, prt or catpart assembly drawings, please contact us directly.

Products List

Contact Us

JACTON INDUSTRY CO.,LTD.

Building 2, No. 1,

Dongcheng Road, Chang An,

Dongguan, Guangdong, China.

Post Code: 523880

Tel: +86 769 8158 5810

Fax: +86 769 8158 5852

Email: sales@jactonindustry.com

Email: jactonjack@gmail.com

Whatsapp: +86 13532830851

Wechat: +86 13532830851

Skype: jactonjack

TradeManager: jactonjack

Online QQ: 2512868631

Website: www.jactonindustry.com

Building 2, No. 1,

Dongcheng Road, Chang An,

Dongguan, Guangdong, China.

Post Code: 523880

Tel: +86 769 8158 5810

Fax: +86 769 8158 5852

Email: sales@jactonindustry.com

Email: jactonjack@gmail.com

Whatsapp: +86 13532830851

Wechat: +86 13532830851

Skype: jactonjack

TradeManager: jactonjack

Online QQ: 2512868631

Website: www.jactonindustry.com

Products

- Screw Jack with Handwheel

- Screw Jack with Motor

- Cubic Machine Screw Jacks

- Cubic Ball Screw Jacks

- Single Face Machine Screw Jacks

- Single Face Ball Screw Jacks

- Single Face Stainless Steel Screw Jack

- Bevel Gear Machine Screw Jacks

- Bevel Gear Ball Screw Jacks

- Super High Speed Screw Jacks

- Electric Cylinder Actuators

- Parallel Electric Linear Actuators

- Inline Electric Linear Actuators

- Electro-Mechanical Linear Actuators

- Compact Cubic Bevel Gearboxes

- Bevel-T Right Angle Gearboxes

- Aluminum Housing Gearboxes

- Servo Spiral Bevel Gearboxes

- Multiple Screw Jack Lifting Systems

Supports

JACTON INDUSTRY CO.,LTD.

Building 2, No. 1,

Dongcheng Road,

Dongguan, Guangdong, China

Post Code: 523880

Phone:+86 769 8158 5810

Email:sales@jactonindustry.com

Building 2, No. 1,

Dongcheng Road,

Dongguan, Guangdong, China

Post Code: 523880

Phone:+86 769 8158 5810

Email:sales@jactonindustry.com

English Site |

Chinese Site |

|

|

JACTON INDUSTRY CO.,LTD | VAT No. 9144190007026567X3 | Website Legal Notice | Privacy Policy | Terms and Conditions

Copyright © 2018 JACTON INDUSTRY CO.,LTD All Rights Reserved | Design By:Jacton | Youtube | Facebook | LinkedIn | Twitter | Pinterest | Google+ | Sitemap