Home » Product Detail

Products

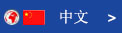

Selection Guide of JTB Series Ball Screw Jacks

Model: JTB-1T to JTB-35T

Brand Name: Jacton

Order Quantity: MOQ 1pc Acceptable

Product Origin: Guangdong, China

Assembly Drawing: 3D (stp, step, model, igs), 2D (dwg, dxf), PDF

Delivery Time: 10-15 Working Days After Payment

Payment Methods: T/T, PayPal, Western Union, MoneyGram

Transportation Modes: Air Freight, Sea Freight

Shipment Port: Shenzhen, Guangzhou, Hongkong

Packages: Strongest Exporting Plywood Cases

Description:

Selection Guide of JTB Series Ball Screw Jacks

Find out more about how to correctly select a complete part number of JTB series ball screw jacks?According to the following sample part number with corresponding additional informaton about JTB series ball screw jacks designs, configurations, end conditions, worm shaft codes and accessories.

Example Order Code: JTB-5T - US - 500 - H - II - C - PP

JTB-1T, JTB-2.5T, JTB-5T, JTB-10T, JTB-15T, JTB-20T, JTB-25T, JTB-35T.

Note: click your required model web pages directly, there are specifications tables and assembly drawings for your reference.

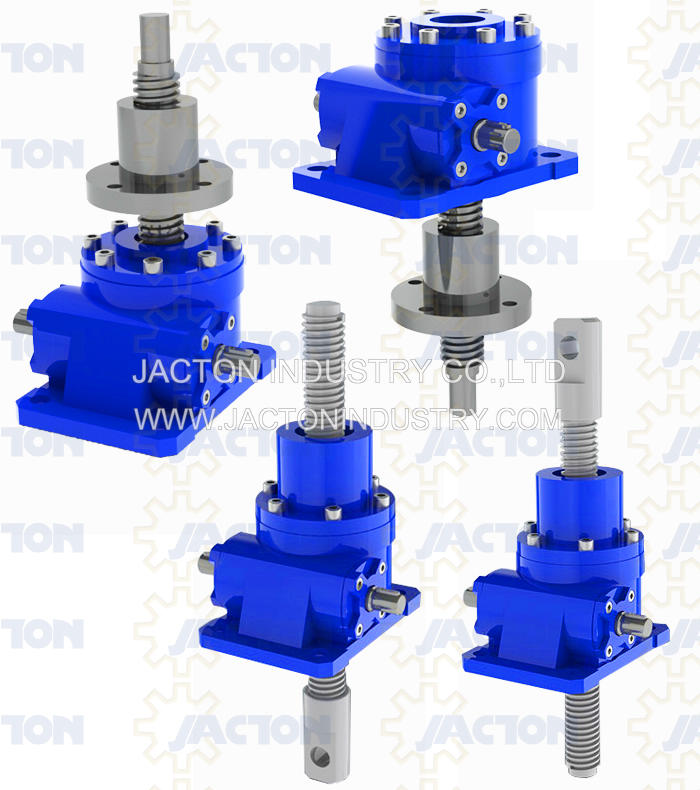

2. Configuration and Designs

US = Upright Translating Screw Design; IS = Inverted Translating Screw Design

UK = Upright Anti-rotation Screw Design; IK = Inverted Anti-rotation Screw Design

UR = Upright Rotating Screw Design; IR = Inverted Rotating Screw Design

Note: The ball screw of a translating screw design jack must be attached to the load (guided) which prevents the ball screw from rotating. Add linear guides, rails or rolls are recommended.

Note: If your application involves a load which is unattached, unguided or the load is free to rotate and not translate, then a anti-rotation screw design jack are required to prevent ball screw rotation. For ball screw jack with anti-rotation device which are supplied with a square nut on the lifting ball screw's end, inside a square cover pipe.

3. Travel Length

There are no standard travel length and all JTB series ball screw jacks travel length are built with customers required.

Note: If compressive loads, must consider the lead screw permissible buckling load.

4. Gear Ratios

Each JTB series ball screw jacks in two worm gear ratios, H: high speed, L: slow speed

| Models | H - High Ratio | Travel Length (mm), Per Turn of Worm (Input Shaft) | L - Slow Ratio | Travel Length (mm), Per Turn of Worm (Input Shaft) |

| JTB-1T | 1/6 | 0.83 | 1/24 | 0.21 |

| JTB-2.5T | 1/6 | 0.83 | 1/24 | 0.21 |

| JTB-5T | 1/6 | 1.67 | 1/24 | 0.42 |

| JTB-10T | 1/8 | 1.25 | 1/24 | 0.42 |

| JTB-15T | 1/8 | 1.25 | 1/24 | 0.42 |

| JTB-20T | 1/8 | 1.50 | 1/24 | 0.50 |

| JTB-25T | 1/10.667 | 1.50 | 1/32 | 0.50 |

| JTB-35T | 1/10.667 | 1.87 | 1/32 | 0.63 |

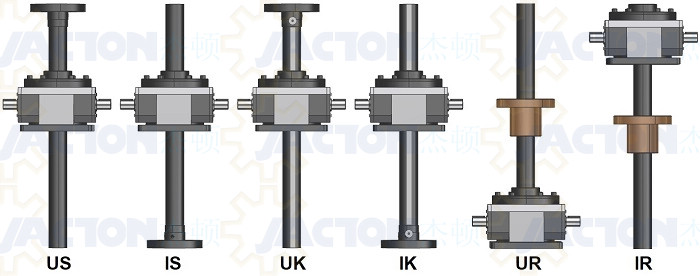

5. Screw End Conditions

Standard trapezoidal screw end conditions include I=top plate (fixing flange), II=clevis end (pivot bearing end), III=plain end, IV=threaded end, VI=fork end, VII=rod end, and no screw end with full threads lead screw.

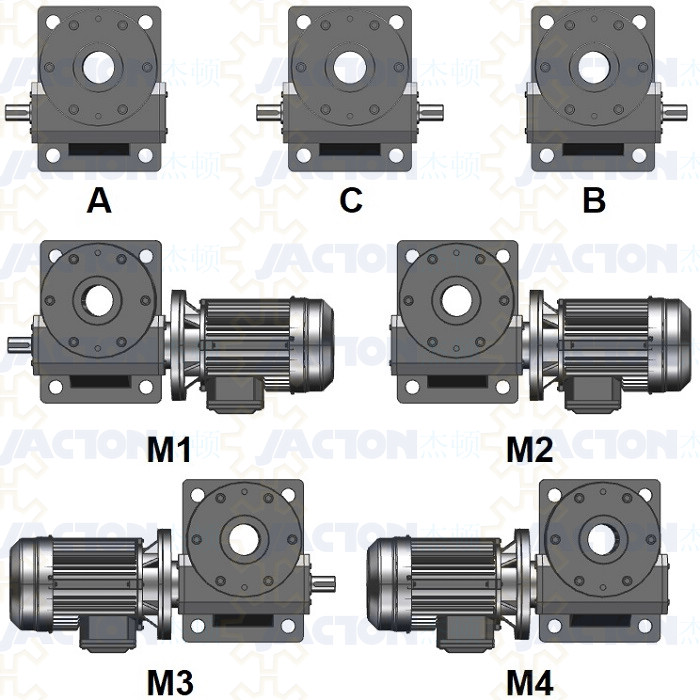

6. Worm (Input Shaft) Codes & Motor Flange Input Codes

A = Left side shaft B = Right side shaft C = Double input shaft

M1 = Left side shaft, Right side motor flange

M2 = Right side motor flange

M3 = Right side shaft, Left side motor flange

M4 = Left side motor flange

Note: Motor flange input types, if need to purchase the motor from us, your purchase orders must be marked. Otherwise, we only sale screw jack with motor flange.

7. Additional Accessories

JTB series ball screw jacks with a comprehensive range of accessories like FC=Flex couplings, UJ=Universal joints, TUJ=Telescopic universal joints, CS=Connecting shafts, HW=Hand wheels, PB=Pillow blocks, FB=Flange blocks, RE=Rod ends, LSB=Linear shafts and bearings, LGB=Linear guides and bearings, TSC=Telescopic spring covers, BB=Bellows boot, PP=Protection tubes, TAP=Trunnion adapter plates, TMB=Trunnion mounting brackets, MF=Motor flanges, WGR=Worm gear speed reducers, HGR=Helical gear reducers, EM=Single phase or three phase induction motors, STM=Stepper motors, SEM=Servo motors, DCGM=DC geared motors, REN=Rotary encoders, LS=Travel limit switches, FIN=Frequency inverters, PIN=Position indicators, SN=Stop nuts, TN=Travel nuts, SNU=Safety nuts.

Warning:

1. Input RPM should not exceed 1500 RPM.

2. Never exceed the JTB series ball screw jacks static and dynamic capacity.

3. Never exceed the power listed in our JTB series ball screw jacks specification tables. If the maximum power recommendation is exceeded, reduce the speed, use a larger capacity ball screw jacks, choose another ball screw jacks ratio.

Products List

Contact Us

JACTON INDUSTRY CO.,LTD.

Building 2, No. 1,

Dongcheng Road, Chang An,

Dongguan, Guangdong, China.

Post Code: 523880

Tel: +86 769 8158 5810

Fax: +86 769 8158 5852

Email: sales@jactonindustry.com

Email: jactonjack@gmail.com

Whatsapp: +86 13532830851

Wechat: +86 13532830851

Skype: jactonjack

TradeManager: jactonjack

Online QQ: 2512868631

Website: www.jactonindustry.com

Building 2, No. 1,

Dongcheng Road, Chang An,

Dongguan, Guangdong, China.

Post Code: 523880

Tel: +86 769 8158 5810

Fax: +86 769 8158 5852

Email: sales@jactonindustry.com

Email: jactonjack@gmail.com

Whatsapp: +86 13532830851

Wechat: +86 13532830851

Skype: jactonjack

TradeManager: jactonjack

Online QQ: 2512868631

Website: www.jactonindustry.com

Products

- Screw Jack with Handwheel

- Screw Jack with Motor

- Cubic Machine Screw Jacks

- Cubic Ball Screw Jacks

- Single Face Machine Screw Jacks

- Single Face Ball Screw Jacks

- Single Face Stainless Steel Screw Jack

- Bevel Gear Machine Screw Jacks

- Bevel Gear Ball Screw Jacks

- Super High Speed Screw Jacks

- Electric Cylinder Actuators

- Parallel Electric Linear Actuators

- Inline Electric Linear Actuators

- Electro-Mechanical Linear Actuators

- Compact Cubic Bevel Gearboxes

- Bevel-T Right Angle Gearboxes

- Aluminum Housing Gearboxes

- Servo Spiral Bevel Gearboxes

- Multiple Screw Jack Lifting Systems

Supports

JACTON INDUSTRY CO.,LTD.

Building 2, No. 1,

Dongcheng Road,

Dongguan, Guangdong, China

Post Code: 523880

Phone:+86 769 8158 5810

Email:sales@jactonindustry.com

Building 2, No. 1,

Dongcheng Road,

Dongguan, Guangdong, China

Post Code: 523880

Phone:+86 769 8158 5810

Email:sales@jactonindustry.com

English Site |

Chinese Site |

|

|

JACTON INDUSTRY CO.,LTD | VAT No. 9144190007026567X3 | Website Legal Notice | Privacy Policy | Terms and Conditions

Copyright © 2018 JACTON INDUSTRY CO.,LTD All Rights Reserved | Design By:Jacton | Youtube | Facebook | LinkedIn | Twitter | Pinterest | Google+ | Sitemap